The white robe and waffle combination was more than just a meal; it was an event

Conclusion

Sectional cold water storage tanks are typically constructed from high-quality materials such as stainless steel, fiberglass, or polyethylene, ensuring durability and resistance to corrosion. The sectional design means that tanks are made up of multiple panels that can be easily transported and assembled on-site. This is especially advantageous in urban areas or locations where access may be limited, as it allows for larger tank capacities without the need for oversized transportation.

The Rise of Fiber Reinforced Polymer Rebar in Modern Construction

Lightweight and Easy Installation

Efficiency and Environmental Impact

Applications of FRP Rebar

The Importance of Cartridge Filter Vessels

Exploring the World of FRP Walkway Manufacturers

- Changing Filters Pre and post-filters need to be replaced periodically, depending on the water quality and usage.

2. Chemical Treatment Systems Chemical treatment involves adding specific chemicals to water to alter its properties. This can include coagulation, flocculation, and disinfection processes. Equipment for this purpose may include chemical dosing systems that accurately dispense necessary substances like chlorine or coagulants to ensure proper water quality.

Another notable advantage is the design flexibility that FRP profiles offer. The fabrication process allows for complex shapes and sizes, enabling engineers and architects to create innovative designs that would be difficult to achieve with conventional materials. This versatility opens doors to creative applications in various fields, from civil engineering to aerospace.

Conclusion

In today's world, the demand for efficient water storage systems is more critical than ever. This is where GRP (Glass Reinforced Plastic) sectional tanks come into play. These tanks offer a modern solution that is both durable and versatile, making them an ideal choice for various applications, including industrial, commercial, and residential water storage.

GRP panel tanks have a wide range of applications across various sectors

Applications of Fiberglass Storage Tanks

The Value Proposition of 1465 FRP Vessels

4. Fuel Storage With the increasing need for efficient fuel storage solutions, these tanks have gained traction in energy sectors. Their design safeguards against leaks, ensuring compliance with safety regulations.

The Benefits of Fiberglass Treads A Durable Solution for Safety and Longevity

The Importance of FRP Stair Treads A Practical Solution for Safety and Durability

Key Features of Pentair FRP Tanks

FRP Vessels A Comprehensive Overview

Molded FRP has found applications in a wide range of industries, including transportation, building and construction, and even consumer goods. In the transportation sector, molded FRP is used for manufacturing lightweight panels for vehicles, which can significantly improve fuel efficiency. In building and construction, it serves as an excellent choice for roofing, cladding, and structural components due to its resistance to corrosion and degradation. The waterproof nature of molded FRP also makes it an ideal material for components exposed to harsh environmental conditions, such as bridges and marinas.

Understanding FRP Technology

3. Slip Resistance

5. Eco-Friendly Options Many FRP manufacturers are now adopting sustainable practices by using recycled materials in their tanks. This makes FRP a more environmentally friendly choice compared to traditional materials.

- Marine Applications The marine industry utilizes FRP vessels for their buoyancy and resistance to saltwater corrosion. These vessels are essential for offshore platforms, vessel hulls, and storage tanks.

What is Metal Bar Grating?

Glass Reinforced Plastic, commonly known as fiberglass, is a composite material made from a polymer matrix reinforced with glass fibers. This combination results in a lightweight yet robust structure, making GRP an excellent choice for various applications, including water storage. When used in the construction of insulated water tanks, GRP provides a strong barrier against environmental factors while maintaining thermal efficiency.

What are FRP Vessels?

SMC panel water tanks are prefabricated tanks made from a composite material that combines fiberglass and resin. This unique construction process results in lightweight yet incredibly strong panels that are resistant to corrosion, high temperatures, and chemical damage. The panels are manufactured in standardized sizes, allowing for quick assembly on-site. Typically, these tanks are modular in design, meaning they can be constructed in various configurations to fit specific space requirements and storage needs.

As the demand for durable and reliable storage solutions continues to rise, fiberglass storage tanks present an attractive option for various industries. Their corrosion resistance, lightweight structure, cost-effectiveness, and customizable designs make them a particularly viable choice for organizations looking to optimize their storage needs.

Advantages of Using Carbon Filter Vessels

Potential Applications

Benefits of FRP Solar Walkways

FRP underground water storage tanks present a modern solution to water storage challenges, combining durability, lightweight construction, and corrosion resistance. As water resource management becomes increasingly critical, understanding the price variables associated with FRP tanks will enable consumers to make informed decisions. While initial costs might seem higher compared to traditional tanks, the long-term benefits of durability and efficiency can make FRP tanks a worthwhile investment. Careful consideration of size, material quality, design, and installation will ensure that consumers choose the best tank for their specific needs, ultimately contributing to more sustainable water management practices.

Fiberglass fence posts are remarkably easy to maintain. Unlike wood, which requires periodic staining or sealing to protect it from theelements, fiberglass is inherently resistant to the challenges posed by time and nature. A quick rinse with water is often all that is needed to keep them looking fresh and clean. This low-maintenance aspect not only saves time for property owners but also reduces long-term costs associated with upkeep and repairs.

One of the most significant advantages of FRP rebar is its resistance to corrosion. Traditional steel rebar is susceptible to rust and deterioration, particularly in environments where moisture, salt, or chemicals are prevalent. In contrast, FRP rebar does not corrode, which substantially extends the lifespan of structures and reduces maintenance costs. This quality makes FRP rebar an ideal choice for projects located in coastal areas or regions with harsh environmental conditions.

The operational mechanism of a pressure vessel water filter is quite straightforward. Water enters the filter under pressure through an inlet. As the water passes through various filtration media, such as sand, activated carbon, or specialized resin, contaminants are trapped and removed. The filtered water then exits through an outlet. The design may utilize multiple layers of different media to target specific contaminants, enhancing the filtration process.

Despite their many advantages, FRP vessels also face challenges, such as stigma regarding their initial cost and concerns surrounding their long-term durability compared to metals. However, as technology in materials science advances, the production processes for FRP are becoming more efficient, leading to cost reductions and improved quality.

Understanding Vessel Types

In conclusion, understanding the pricing dynamics of fiber water tanks is crucial for consumers and businesses alike. By weighing the costs against the benefits and considering factors like size, quality, and brand, buyers can make informed decisions that not only meet their water storage needs but also align with sustainable practices in an era of growing environmental consciousness.

Conclusion

Applications in Various Industries

After disinfection, the treated water is ready for distribution through pipelines to homes, businesses, and industries. Regular monitoring and maintenance of the water supply system are vital to ensure its safety and quality. Additionally, stringent regulations and guidelines set by organizations like the U.S. Environmental Protection Agency (EPA) and the World Health Organization (WHO) help safeguard public health by establishing acceptable levels of contaminants in drinking water.

Durability and Longevity

- - Marine Applications Their resistance to saltwater corrosion makes FRP guardrails suitable for marine environments, such as docks and coastal paths.

What Influences the Price of FRP Rods?

Future Prospects

In addition to safety, modular handrails can significantly enhance the functionality of a space. For instance, they can be integrated with other elements such as glass panels, lighting features, or even automated systems that can provide additional support in public environments. This adaptability makes them ideal for both residential staircases and commercial buildings.

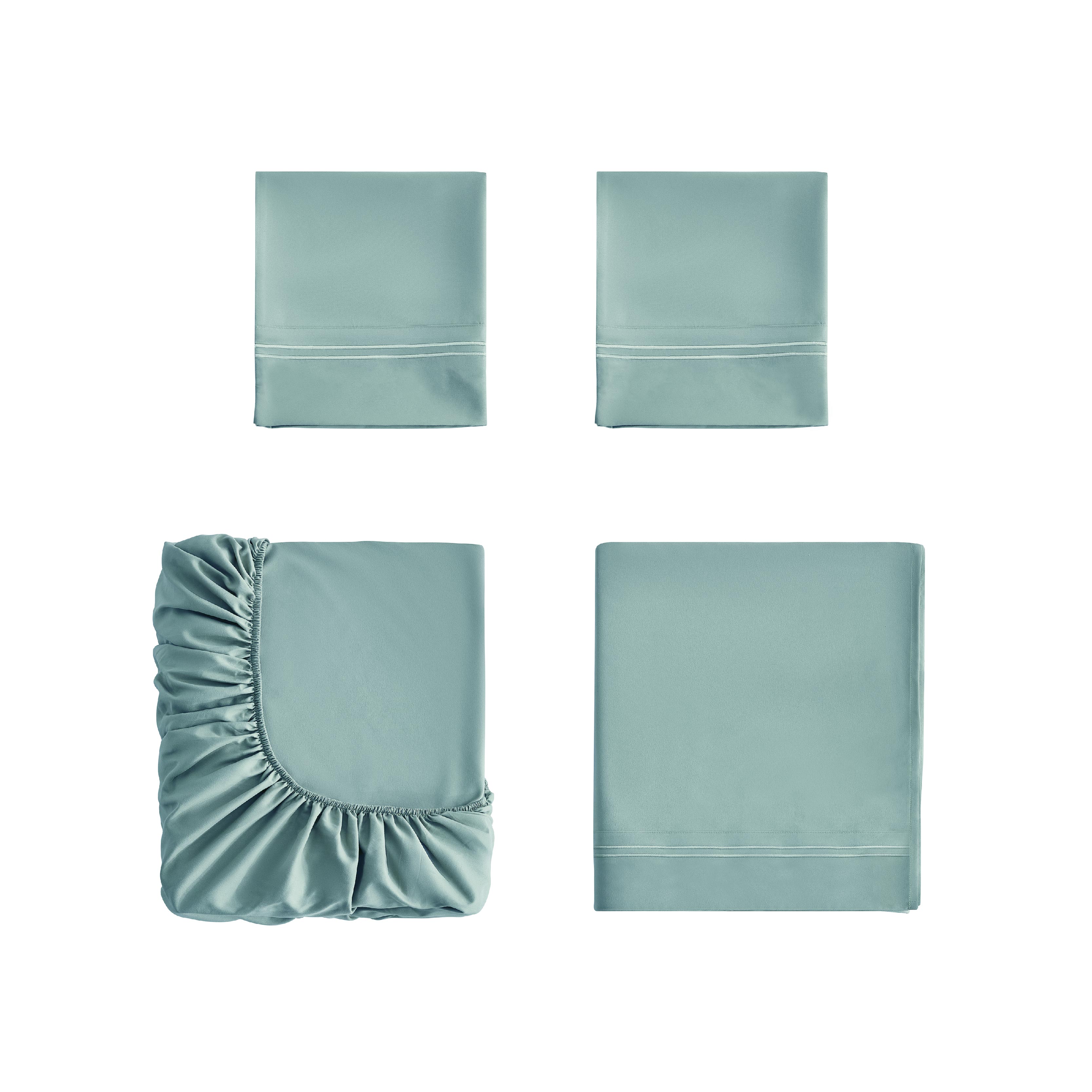

Whether it's an unusual bed size, a preference for eco-friendly materials, or hypoallergenic options for allergy sufferers, custom bedding companies rise to the occasion Whether it's an unusual bed size, a preference for eco-friendly materials, or hypoallergenic options for allergy sufferers, custom bedding companies rise to the occasion

Whether it's an unusual bed size, a preference for eco-friendly materials, or hypoallergenic options for allergy sufferers, custom bedding companies rise to the occasion Whether it's an unusual bed size, a preference for eco-friendly materials, or hypoallergenic options for allergy sufferers, custom bedding companies rise to the occasion

It gently draws moisture away from your skin, helping you dry off quickly while still maintaining a soft, gentle feel against your skin It gently draws moisture away from your skin, helping you dry off quickly while still maintaining a soft, gentle feel against your skin

It gently draws moisture away from your skin, helping you dry off quickly while still maintaining a soft, gentle feel against your skin It gently draws moisture away from your skin, helping you dry off quickly while still maintaining a soft, gentle feel against your skin